stainless steel pricelist

Home

Home- · kitchen plinth sealing strip factory

- · shower frame seal strip exporter

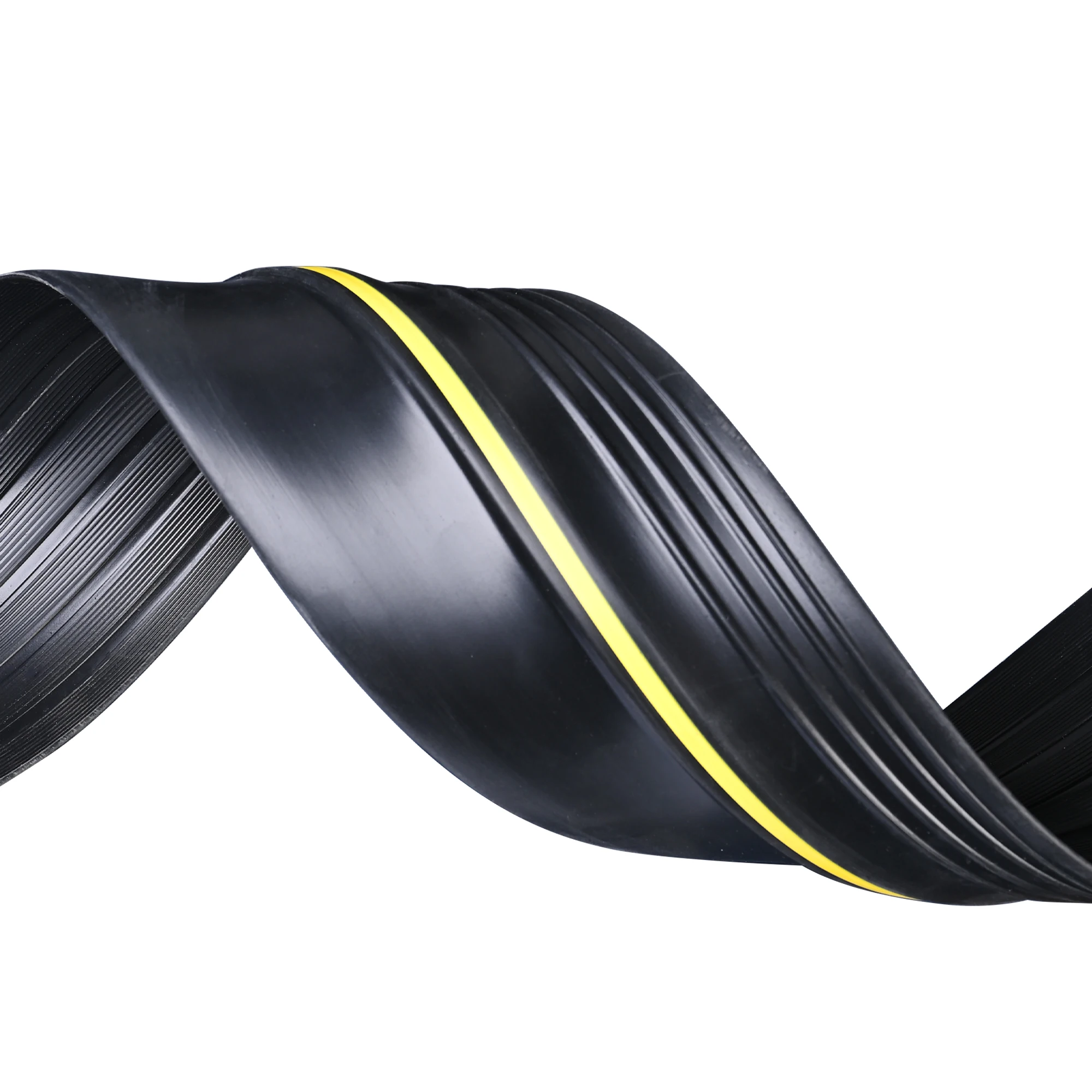

- · sealing strip products

- · d shaped rubber seal strip product

- · oem window rubber seal strip

- · door bottom threshold seal strip pricelist

- · sponge seal tape companies

- · oem door rubber seal strip

- · corner shower door seal strip pricelist

- · silicone rubber plastic strip exporters

The Boom Cylinder Seal Kit, therefore, was more than just a utilitarian tool; it was a medium of expression, a visual language that transcended time and space The Boom Cylinder Seal Kit, therefore, was more than just a utilitarian tool; it was a medium of expression, a visual language that transcended time and space

The Boom Cylinder Seal Kit, therefore, was more than just a utilitarian tool; it was a medium of expression, a visual language that transcended time and space The Boom Cylinder Seal Kit, therefore, was more than just a utilitarian tool; it was a medium of expression, a visual language that transcended time and space

Similarly, in aerospace applications, a seal failure could jeopardize the entire mission, risking the lives of crew members and the success of the endeavor Similarly, in aerospace applications, a seal failure could jeopardize the entire mission, risking the lives of crew members and the success of the endeavor

Similarly, in aerospace applications, a seal failure could jeopardize the entire mission, risking the lives of crew members and the success of the endeavor Similarly, in aerospace applications, a seal failure could jeopardize the entire mission, risking the lives of crew members and the success of the endeavor